As a result, plug covers are extremely useful in industries such as chemical and food processing, industrial, telecommunications, marine, military, commercial, and residential, where they are widely used for infant safety. Read More…

Our customers find we have the highest standards when it comes to quality, and delivery. Quail Electronics is a worldwide power cord supplier, offering power cords and various other products.

All of our power cords are tested and stand up to rigorous demands of everyday application. We serve a global market including the United Kingdom, Ireland, Germany, Switzerland, Austria and of course the United States.

Our plug adapters are guaranteed to bring you a lifetime of value. Our staff is committed to bringing you only the most reliable products that are available. We will find solutions for your cord needs regardless of how difficult the job may be.

At Conntek, we have many years of experience manufacturing electronic connectors for a variety of industries. We believe in offering a variety of services to our customers, and we extensively test all of our products for multiple environments. You can learn more about us when you contact us today or visit us online! We can't wait to hear from you!

Qualtek Electronics is a RoHS compliant & ISO 9001:2000 certified supplier of power components including cordsets, international and domestic power cords, circuit breakers, AC receptacles and more. We also provide fan accessories, heat shrinkable tubing, EMI power line filters and cable assemblies.

More Plug Cover Manufacturers

Plug covers are electrical outlet coverings. Many industries require plug covers, especially industrial manufacturers, due to the concern for employee safety as well as the frequent use of chemicals and other corrosive agents.

In response to harsh environments, plug covers are typically made from materials that are highly corrosion-resistant. Additional features such as thermal stability and temperature resistance may also be provided depending on the material used, and at this point, the plug covers become much more application-specific.

Not only functional and necessary equipment, plug covers may also be aesthetically pleasing, as they are available in a wide range of colors and designs ranging from plain and basic to the highly complex.

Since plug covers are typically designed based on a specific application's requirements, there is a wide range of materials that are used based on their various characteristics. Some common materials that are used to make plug covers include stainless steel, aluminum, ethyl vinyl acetate (EVA), polyethylene (PE), and polypropylene (PP).

As a popular industrial metal, aluminum is used for plug covers because it has both good electrical and thermal conductivity as well as being highly oxidation-resistant. A thermoplastic elastomer, EVA is used for plug covers because it is extremely resistant to cracking and able to retain flexibility at low temperatures.

Another popular industrial metal, stainless steel is used to make plug covers because it has high corrosion and chemical resistance. As a common industrial thermoplastic, PE offers excellent electrical properties but has poor temperature resistance.

Lastly, PP has the unique characteristics of outstanding bi-axial strength as well as cold flow and yield elongation properties. Much less common materials such as natural rubber and styrene butadiene (SBR) may be used for applications requiring unique attributes such as an increased resistance to certain chemicals like oils or hydrocarbons.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

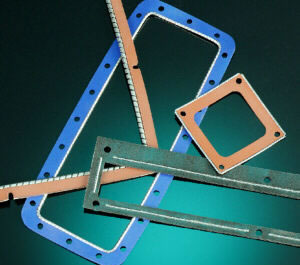

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services