Cord sets are electrical cables used to connect an appliance or piece of equipment to a main power source. When connected, they provide electrical energy. They are also sometimes known as power cords, power supply cords, or electric cords. They are distinct in that they have connectors molded to their cords at each end, and they are detachable from both the power supply and the electrical equipment. Read More…

Our customers find we have the highest standards when it comes to quality, and delivery. Quail Electronics is a worldwide power cord supplier, offering power cords and various other products.

All of our power cords are tested and stand up to rigorous demands of everyday application. We serve a global market including the United Kingdom, Ireland, Germany, Switzerland, Austria and of course the United States.

Our plug adapters are guaranteed to bring you a lifetime of value. Our staff is committed to bringing you only the most reliable products that are available. We will find solutions for your cord needs regardless of how difficult the job may be.

At Conntek, we have many years of experience manufacturing electronic connectors for a variety of industries. We believe in offering a variety of services to our customers, and we extensively test all of our products for multiple environments. You can learn more about us when you contact us today or visit us online! We can't wait to hear from you!

Qualtek Electronics is a RoHS compliant & ISO 9001:2000 certified supplier of power components including cordsets, international and domestic power cords, circuit breakers, AC receptacles and more. We also provide fan accessories, heat shrinkable tubing, EMI power line filters and cable assemblies.

More Power Cord Manufacturers

Cord sets are electrical cables used to connect an appliance or piece of equipment to a main power source. When connected, they provide electrical energy. They are also sometimes known as power cords, power supply cords, or electric cords. They are distinct in that they have connectors molded to their cords at each end, and they are detachable from both the power supply and the electrical equipment.

Applications

Cord sets find applications in numerous industries and everyday scenarios. One of the most common uses is in the consumer electronics sector, where cord sets are essential for connecting devices like computers, TVs, and gaming consoles to power outlets. In the industrial realm, meanwhile, cord sets play a vital role in powering machinery, equipment, and tools, ensuring seamless operations in factories and construction sites. Medical settings also utilize specialized cord sets for medical devices and equipment, ensuring patient safety and reliability. Additionally, cord sets are extensively employed in the automotive industry to power electric vehicles and charge plug-in hybrids. The versatility of cord sets extends to outdoor applications such as powering outdoor lighting, garden equipment, and camping accessories. Overall, cord sets serve as crucial connectors, facilitating the safe and efficient transfer of electrical power in a wide range of industries and everyday environments.

The History of Cord Sets

The earliest power distribution system in the USA, an ancestor of the cord set, was created in 1882 in New York City, by Thomas Edison. (He created one much like it earlier that year in London.) The system carried DC power from his power plant, Pearl Street Station, to customers within the surrounding mile. It relied on copper rods wrapped in jute (a vegetable fiber) and placed in rigid pipes with an asphalt-esque compound for insulation.

Later in the 1880s, people began using vulcanized rubber, which had been patented in 1844 by Charles Goodyear, as cable insulation as well. It gained such popularity that, in 1897, rubber insulated cable was installed to house 11,000-volt circuits for the Niagara Falls power project. By World War II, cables used during war were being made with polyethylene and synthetic rubber insulation.

Power cords and cord sets in the American home have gone through many iterations over time as well. First, they used bare and cloth covered wires installed with staples. Of course, they quickly realized the dangers of bare and poorly covered wire. Next, through the 1930s, they relied on insulated cord sets that, like those discussed above, were covered in asphalt saturated cloth or rubber. In 1906, for example, manufacturers introduced armored cable, known more commonly by the name “Bx.” This cable featured a flexible steel sheath with two cloth- covered, rubber insulated conductors. Another popular cord set type was introduced in 1922. This assembly featured rubber insulated wires, jackets made of tar impregnated woven cotton cloth, and waxed paper filler.

In the 1950s, manufacturers introduced early two wire PVC-insulated cables, known as “Romex” cables. In the 1960s and 1970s, American homes were encouraged to use aluminum wire as a cheap replacement for copper. However, this was ill-advised and is no longer recommended, as it is unsafe due to corrosion. A more positive shift made in the 70s was the banishment of asbestos as an insulator in cloth wire, when the scientific community came to the consensus that asbestos is extremely hazardous to human health. Today, many American homes use cord sets made from three-wire PVC-insulated cable, a product also known as Romex. They also work with power adaptors, like the increasingly popular USB adaptor.

Design

Construction

The standard power cord set is simply made; it consists of a flexible cord with electrical connectors at both ends (one female and one male), a plug and a plug cover. The cord is made up of highly conductive wire, sheltered by an insulative material, sealed in a protective outer jacket. One end of the cord is attached to a molded electrical plug, while the other is usually a molded electrical receptacle.

Materials

Typically, the conductive wire used in cord sets is copper. This has been a constant for virtually the whole of the cord set’s existence. Insulative materials are chosen for their temperature rating and non-conductive nature. Examples of insulative materials cord set manufacturers commonly use include: PVC, semi-rigid PVC, plenum PVC, polyethylene, polypropylene, polyurethane, chlorinated polyethylene, nylon, thermoplastic rubber, styrene butadiene rubber (SBR), silicone, fiberglass, ethylene propylene rubber (EPR), plain rubber, chlorosulfonated polyethylene (CSPE), ethylene propylene diene monomer (EPDM) and thermoplastic elastomers (TPE), among others. Jacketing materials are typically some type of thermoplastic or rubber, such as: TPE, PVC or neoprene. The choice of which varies based on characteristics, like: oil resistance, heat resistance, moisture resistance, etc.

Design and Customization Considerations

Cord construction is subject to a number of standard regulations, relating to voltage ratings, current, wire length and diameter, maximum cable temperature, jacket material, and the type of molded plug and female receptacle to be used. While manufacturers must always determine cord construction based on standard regulations, they can customize them based on application requirements. For instance, wire shape (flat or round) and wire gauge are determined by the requirements of the application for which the power cable is intended. Likewise, jacket material is also determined by application requirements. For example, for rugged outdoor use, a jacket will be made of waterproof material. Cords placed in an area of high electromagnetic interference may require jackets with extra protection. Manufacturers may also customize your plug power cord type (rotating, snap-on, screw-on, locking, etc.), your cordset color and/or your cordset length.

Features

Cord sets can transfer electrical power using either direct electrical currents (DC) or alternating electrical currents (AC). However, most modern cords feature AC. An AC power cord is more efficient and transmits power over long distances much better than a DC power cord. Their force is measured in units of volts, or volt amps.

To work, cord sets must be plugged into an outlet or electrical receptacle. Cord sets can be detached at both ends, from both the electrical equipment and the power supply. The female connector connects to the equipment or appliance, while the male plug attaches to the outlet or electrical receptacle.

The cords can be permanently molded to a plug or they may require a separate power adaptor, also known as an AC adaptor or outlet adaptor. The two most common plug types in North America are called Type A and Type B plugs. Type A plugs have two conducting prongs, while Type B have three. The third prong of the latter supplies the cord with an additional flow of electricity and connects it to a grounding rod. The best connections come from a tight fit between the plug and the wall socket it fits in.

Power adaptors plug into a wall outlet and convert AC into DC voltage. They can be made in a wide variety of styles, including: North American, International, Universal, IEC, double, single and USB. Additional cord set components may include: a leak detection system, electrical fuses to protect against voltage surges, protective material to reduce the influence of electromagnetic energy and a system for checking voltage.

Types

Some specialized cord sets include business machine cords, heavy duty cords, hospital plugs, NEMA power cords, right angle power cord sets, power strips and extension cords.

Business Machine Cord

Business machine cords are made for use with computers and computer-related equipment.

Heavy Duty Cord

Heavy duty cords are designed to withstand the rigor of harsh, heavy-usage environments found as a part of many industrial and commercial applications. To create a non-slip grip, their heads are large and flat, with deeply contoured ridges; to protect the connection between the cord and plug, they have a heavy, molded strain relief shroud.

Hospital Plug

To create the durability that high-stakes medical equipment applications need, hospital plugs have conductors that are welded or soldered to solid brass pins and blades.

NEMA Power Cord

NEMA power cords are those that are made to match the exact voltage capacity and electrical receptacle configuration standards of NEMA.

Right Angle Power Cord

Available with either two-conductor or three-conductor plugs, right angle power set cords are designed to allow users to plug electrical equipment into small spaces without bending or otherwise damaging the cord.

Power Strip

Power strips are blocks of electrical sockets attached at one end to a flexible cable that (typically) plugs into a wall. Their purpose is to allow multiple electrical devices to be powered at once from a single socket. They’re often used in proximity to multiple devices, such as: computer systems, power tools, lighting systems, audio and video systems and general appliances. They are suited for both the home and the workplace. To avoid overloading a short circuit, power strips may come with a circuit breaker. Other names for the power strip include: poly socket, multiple socket, multiple/multi socket, multi box, power board, power bar, plug board, extension block, trailing socket, trailing gang or plug bar.

Extension Cord

Extension cords are extra-long cords that carry electrical currents hundreds of feet away from an outlet. They are made to power specialty equipment, like stage lighting equipment, power tools and emergency medical defibrillators, that is used away from a convenient power source.

Advantages of Cord Sets

Cord sets offer a plethora of advantages that cater to the needs of both consumers and industries. The plug-and-play nature of cord sets simplifies the installation process, allowing users to connect their devices quickly and easily without requiring specialized knowledge. This convenience is particularly valuable in homes, offices, and public spaces where users frequently switch and relocate electronic equipment. Additionally, cord sets incorporate safety features like grounding and insulation, which provide an extra layer of protection against electrical accidents, ensuring the well-being of users and the longevity of connected devices.

The standardization of cord set plug types and voltage ratings ensures uniformity and compatibility across various devices and regions. This standardization makes it possible for users to interchange cords between devices without worrying about compatibility issues. Moreover, it facilitates international travel, as travelers can bring their devices and simply use a compatible cord set with the local power outlets.

The cost-effectiveness of cord sets is a significant advantage in both consumer and industrial settings. Custom wiring can be expensive and time-consuming, whereas cord sets eliminate the need for such bespoke solutions in many cases. Standardized cord sets are mass-produced, leading to economies of scale and reduced manufacturing costs, ultimately benefiting consumers with affordable pricing.

Furthermore, the versatility of cord sets cannot be overstated. They come in various lengths, configurations, and designs to accommodate diverse applications, from small household appliances to heavy-duty industrial machinery. This adaptability ensures that cord sets can meet the specific power requirements of different devices and environments.

In summary, the advantages of cord sets encompass their simplicity, safety, compatibility, cost-efficiency, and adaptability. These factors contribute to their widespread use across numerous industries, including consumer electronics, healthcare, manufacturing, automotive, and more. Whether it’s charging our smartphones or powering heavy machinery in factories, cord sets play an integral role in ensuring a reliable and efficient transfer of electrical power.

Accessories

Cord set accessories play a crucial role in enhancing the versatility and safety of cord sets, catering to various needs and specific applications. Adaptors, for instance, offer a practical solution for travelers or users dealing with different plug standards, enabling seamless connectivity between devices and power outlets. Meanwhile, fuses for overcurrent protection are vital safety components, automatically breaking the circuit in case of current overload to prevent damage to devices and mitigate electrical hazards. Additionally, insulating tape and shrink tubing provide electrical insulation, shielding connections from moisture and contaminants, while high-temperature silica tape ensures the protection of wires in extreme heat environments, such as industrial or automotive settings.

Likewise, grip seals serve as a practical means of securing connections, preventing accidental disconnection and providing strain relief. Cable cutters and wire strippers, on the other hand, are indispensable tools for clean and precise wire preparation, ensuring optimal electrical performance and reliable connections. Cable sleeves organize and protect bundled wires, reducing the risk of tangling and shielding them from external damage. Pilot lamps act as valuable indicators, informing users about power presence or specific device functions.

Leakage current detectors are especially critical in medical or sensitive equipment, ensuring electrical safety by detecting any unintended current flow between the system and ground. To determine the need for specific cord set accessories, one must consider the specific requirements and potential risks associated with the electrical connections. Whether it’s ensuring compatibility during international travel, protecting against power fluctuations, or organizing and insulating wires in challenging environments, cord set accessories offer practical solutions to make electrical operations more efficient, reliable, and safe.

Proper Care for Cord Sets

Proper care and maintenance of cord sets are essential to ensure their longevity, safety, and optimal performance. To start, it’s crucial to handle cord sets with care, avoiding unnecessary bending or pulling on the cord to prevent internal wire damage. Regularly inspect the cord for any signs of wear, fraying, or damage to the insulation, and promptly replace damaged cords to avoid potential electrical hazards. Keep cord sets away from heat sources, sharp objects, and moisture to prevent deterioration and electrical malfunctions. When disconnecting cord sets, always grasp the plug firmly and avoid pulling on the cord itself.

To clean cord sets, use a dry cloth or a slightly damp cloth if needed, and make sure they are completely dry before plugging them in again. Avoid using solvents or harsh cleaning agents that could damage the insulation or connectors. When not in use, store cord sets in a clean and dry location, coiling them loosely to prevent kinks or stress on the wires.

Additionally, ensure that cord sets are rated appropriately for the intended load and application. Overloading cord sets can lead to overheating and pose fire risks. If using extension cords for outdoor or temporary applications, choose those rated for outdoor use and protect the connections from rain or other environmental elements.

Regularly inspect the plugs and connectors for any signs of loose or damaged parts, and if necessary, tighten or replace them. It’s also a good practice to unplug cord sets when not in use, as this helps reduce energy consumption and minimizes the risk of electrical accidents.

By following these care guidelines and practicing safe usage, one can prolong the life of their cord sets, ensure their safety, and maintain efficient electrical performance in various applications.

Standards

In the United States, the National Electrical Manufacturers Association (NEMA) is responsible for setting forth regulations on cord voltage capabilities, electrical plugs, and receptacle configuration. These standards are designed to secure operator safety and product quality. American Wire Gauge (AWG) designates standards for cord wire sizes and voltage capacities. (This means that appropriate wire size is determined by the amount of voltage required to flow through it.) Other countries adhere to their own standards, which is why their electrical cord set components have different voltages and plug configurations, and why travelers must use international power cords or plug adapters while abroad.

In addition, an excellent organization that partners with companies to provide testing for adherence to standards is UL. UL helps ensure quality and strengthen sustainability for products used in both the USA and abroad. A manufacturer that works with UL is a big advantage.

Things to Consider

For an important industrial, commercial or medical application, you need a high-quality cord set that matches your specifications. If you end up with the wrong one, you risk system malfunction, leading to costly, time-consuming or even dangerous lapses in function. You also risk shortages that could spark fires. If you want to be absolutely certain that you have the right cords with the best material composition for you, you need to work with a cord set professional. We know choosing one supplier from the countless suppliers out there can be daunting. That’s why we’ve taken the time to search the crowd for you and come up with the best companies in the business today. You can find our choices by browsing this page; we’ve interspersed their profiles throughout. Browse their profiles and websites, and then reach out to a few in whom you’re interested. While searching, remember: the right manufacturer won’t be the one that just offers great deals, but rather the one willing to put in the time and effort to create products that will serve you well. Hold out for that manufacturer.

Check out our Power Cords website

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

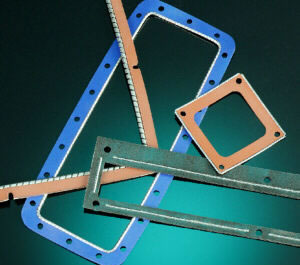

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services