The majority of electrical receptacles run on alternating current, or AC power, and they consist of live or phase components, neutral components, and earth or ground components, each allowing the flow of electrical energy through the receptacle. Read More…

Our customers find we have the highest standards when it comes to quality, and delivery. Quail Electronics is a worldwide power cord supplier, offering power cords and various other products.

All of our power cords are tested and stand up to rigorous demands of everyday application. We serve a global market including the United Kingdom, Ireland, Germany, Switzerland, Austria and of course the United States.

Our plug adapters are guaranteed to bring you a lifetime of value. Our staff is committed to bringing you only the most reliable products that are available. We will find solutions for your cord needs regardless of how difficult the job may be.

At Conntek, we have many years of experience manufacturing electronic connectors for a variety of industries. We believe in offering a variety of services to our customers, and we extensively test all of our products for multiple environments. You can learn more about us when you contact us today or visit us online! We can't wait to hear from you!

Qualtek Electronics is a RoHS compliant & ISO 9001:2000 certified supplier of power components including cordsets, international and domestic power cords, circuit breakers, AC receptacles and more. We also provide fan accessories, heat shrinkable tubing, EMI power line filters and cable assemblies.

More Electrical Receptacle Manufacturers

Made with insulating materials such as nickel, silver, plastic and galvanized steel, sockets are formed with two slots and an optional extra slot known as a grounding hole which is used in some electrical plugs for polarization.

Designed to receive a conventional electrical cord and plug, common electrical receptacles run on the United States standard 120-volt system. However, heavy-duty 240-volt receptacles can be designed for equipment that requires a higher voltage such as electric ranges or industrial machinery.

As with any component that is used in the transferring of electrical energy, there are important safety precautions to be considered. Electrical receptacles can cause shock and electrical hazards due to deterioration, damage, or misuse resulting in personal injury, death, and/or property damage from electrical fires.

Frequent usage is a common cause of deterioration in receptacles, especially in high-traffic areas such as kitchens and bathrooms. Therefore, high-quality materials and the consistent maintenance and upkeep of receptacles is important, especially in industrial and manufacturing settings.

The National Electrical Manufacturer's Association (NEMA) sets stringent quality standards for power cords, sockets, and components in the US, and other countries around the world which use different voltages and electrical plug and receptacle structures set their own testing standards for general safety purposes.

There are, however, technologies in place to reduce the potential hazards of electrical receptacles. Polarization, for example, helps control the connection between the electrical plug and the socket. Other measures include tamper resistance components and corrosion resistant materials, especially in receptacles designed to be exposed to harsher environments.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

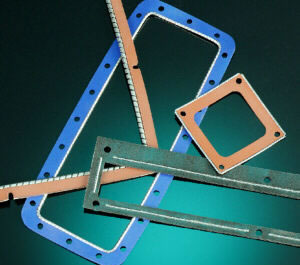

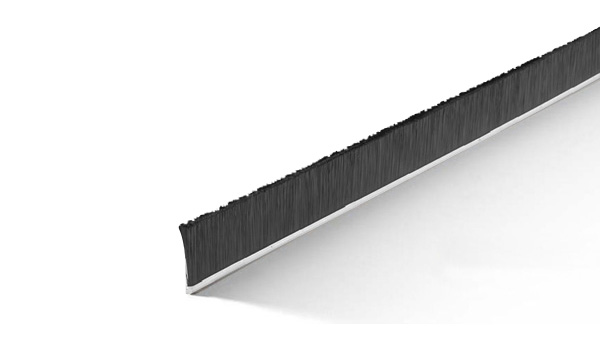

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services